I don't know how many altogether have seen my vids on takedown/reassembly - basic tho they are. But, in the reassembly vid I put the recoil assembly back into place with no use of channel locks, barrel in place - just done by hand with some jiggling and minor cussing

I have done a very subtle mod' to two components - which IMO can make that proceedure just a tad easier. Let me stress right now - it is NOT Rohrbaugh approved - tho having said that I cannot believe for one moment it would be frowned upon! It is ONLY - food for thought and seemed worth mentioning.

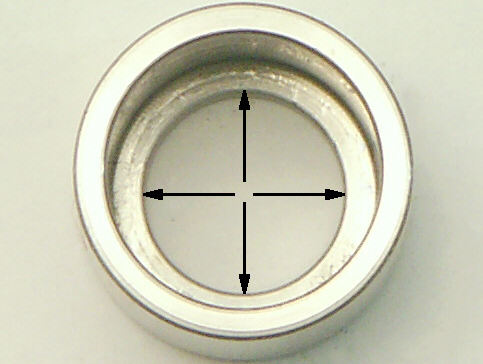

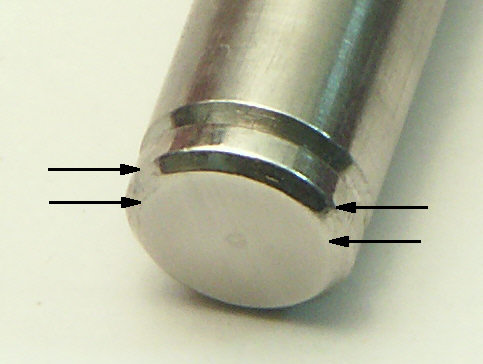

Look at the pics below - you will see the inside of the end cap - and the end of the guide rod. Now, imagine if you try to insert the assembly in as I did - by hand - it is necessarily starting at an angle relative to the barrel and so also, to that hole you are targeting in the slide. That angle of approach then makes the side of guide rod nearest barrel press against the inside complementary surface of the end cap.

Of course, the guide rod end has a machined chamfer but IMO each side of that chamfer is still quite ''sharp'' - a crisp edge - no criticism I might add. The inside of the end cap does not have any discernible chamfer - it seems a relatively sharp edge - no real major reason that it should have any extra machining - in theory!

My contention is - those ''sharp'' edges when abutted at this angle of approach - tend to snag - making it harder to get guide rod thru end cap. That is where it ''hangs up'' most times.

My suggestion (which again I stress is mine only - not a Rohrbaugh one!), step one - is to wrap a small piece of 600 grit emery paper round a small piece of flat hardwood ..... and then apply both edges of the guide rod chamfer (one at a time) to the abrasive, rotating guide rod by twirling in fingers to make process even. Now this will barely remove any metal to speak off - what it will do is make those chamfer edges the merest bit less sharp. Almost a polish plus a bit! Concentrate on the major diameter of the chamfer.

Now stage two - the end cap. Be inovative here - I found a small screwdriver which had a handle tapering where blade enters. I was able to wrap some 600 grit round that - insert whole deal into rear of end cap - and then lightly rotate cap on that formed abrasive sheet. Do this a good few times. You will not see a huge difference - it would take high magnification to see a change but IMO it takes off just a whisker of sharp edge. A tapered piece of dowel would do OK as a former - bound to be something you can find.

Now this does not suddenly make the recoil assembly a breeze to reinstall - it's still a fiddle but I do think this helps just ease the process and no metal is removed that can be IMO in the least prejudicial - it is probably hard to even measure!

As usual I am being very verbose but - just trying to give you a mental picture of what I did. The arrows in the pics are there purely to make quite sure you can identify the edges I am describing smoothing, circumferentially.